Our Strengths

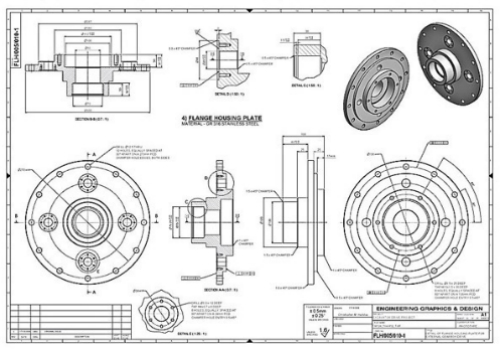

In its simplest form, recipes are the parameters of the equipment associated with the individual product variants. These parameters are performed and stored in the controller during development of the equipment or is performed immediately before the series or the item are about to be produced. More advanced recipes are various tools, PLC-programs, Vision Data and programmes with workflows for robots associated with the single product variants.

Utilization of vision-controlled robots – i.e. “sensing robots” – allows automation productions in small series with frequent re-alignments, at no extra costs.

Using vision control in the robots often eliminates expensive fixtures and allows for fulfilling high demands of flexibility. Read more about vision-controlled robots.

Using robotics technology enables to perform change overs several times a day, and it only takes a few minutes. This is an advantage in production companies with small series. Read more about robotics technology.

Semi automation may be relevant if the product program is very diversified and the volume of the single variants is small.

Using modularity the machine is performed with modules with separate controls which enables the machine lines to be established or re-build to produce future variants by changing one or more modules.